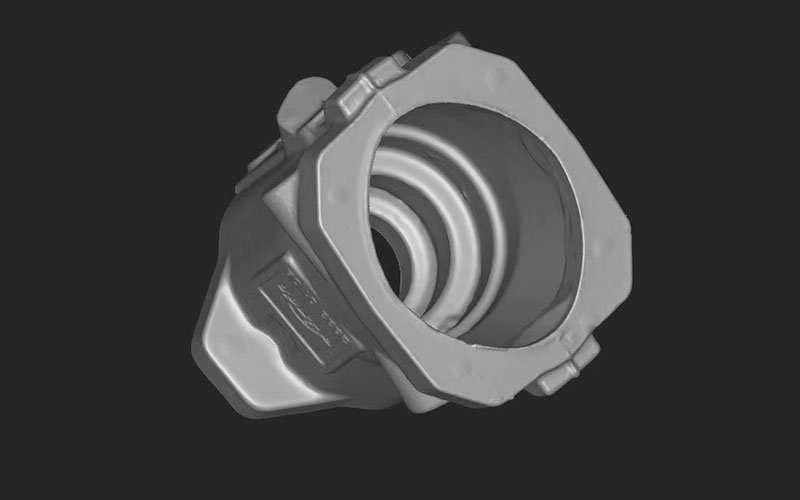

3D Scanning a Casting Product with iReal 2E

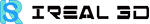

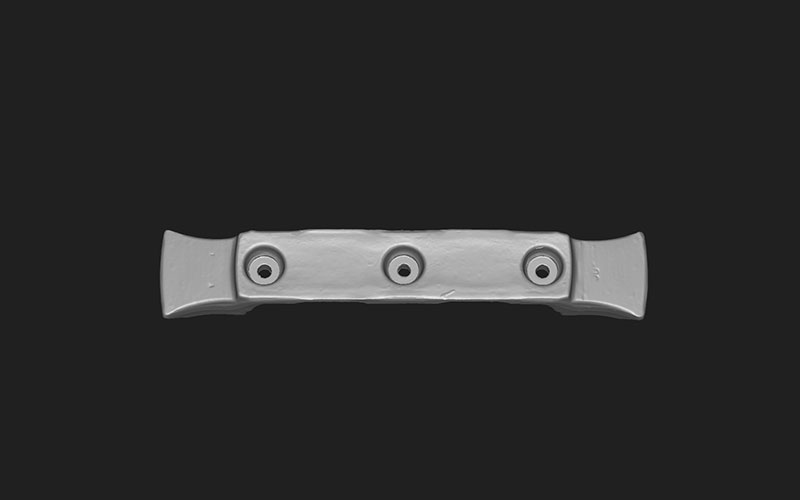

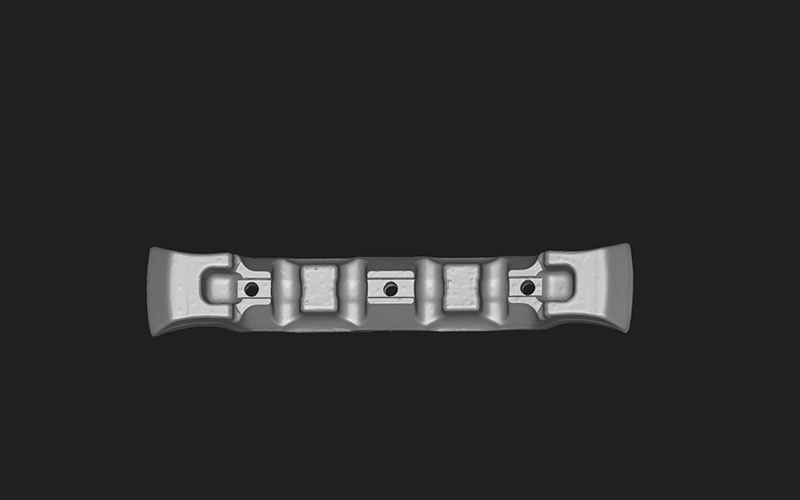

As iReal software and algorithm are increasingly developing, iReal 2E has successfully engaged in some industrial 3D scanning tasks in reverse engineering with outstanding performance. This article demonstrates a case study where iReal 2E helped capture high-precision data of a casting product as data support for its reverse engineering.

When the layout drawing of a product (such as a mechanical part) is lost, 3D scanners are used to capture the product’s 3D data. Then, turn the scan data into a CAD model using a professional reverse engineering software like Geomagic Design X. This process includes feature identification and surface alignment. In this way, the layout drawing can be obtained for future mass production.

As for some casting companies with limited budgets and lower requirements for precision, iReal 2E 3D scanner is an excellent choice! With basic precision of 0.1 mm, alignment precision of 0.3 mm/m, and the highest resolution of 0.2 mm, its 3D scanning ability meets the requirement for medium and large-sized casting products.

As illustrated above, iReal 2E 3D handheld scanner is a cost-effective choice for medium to large-sized industrial parts with no fewer details. If you are looking for a reverse engineering solution with higher requirements for precision and resolution, or the object you scan is small, then instead of iReal 2E, it is strongly recommended that you consider the industrial-grade laser 3D scanners from SCANTECH 3D, such as SIMSCAN or KSCAN-Magic. For more information, feel free to drop us a message or visit SCANTECH 3D.