3D Scanner Selection Guide for Plant Growth Morphology Analysis

05/10/22

The demand for 3D scanning for plant growth and morphology analysis is increasing gradually in recent years, which is mainly because of the high efficiency, high accuracy and convenience brought by 3D scanning technology. When people choose a 3D scanner for plant growth and morphology study, they tend to consider the following factors: price, whether sticking markers is required, accuracy, finess, color scanning ability, brand recognition, and so on. It is true that those factors are crucial to the purchase decision, however, some other factors should also be considered equally.

Factors to consider when choosing a 3D scanner for plant scanning

Apart from the factors mentioned above, we will introduce you to four things you should also consider when choosing a 3D scanner for plant studies.

1. Data collection ability

– Material adaptability (for an object with black and shiny surface or highly-reflective surface, can the scanner work directly on it or is the contrast imaging powder a must for the performance);

– Data integrity (whether the dead corners, deep holes and grooves are scanned completely in fine details);

– Data accuracy (whether the details/textures are restored accurately and whether the edges/corners are clearly seen);

2. Precision

The precision determines whether the scan data is useful and where to use them. Therefore, we need to ascertain the four factors: the requirement for precision (varied by each scanned object) and the data consistency; is it for direct production purpose; is there a distortion (such as edge warp)? Plus: In addition, the point accuracy will affect the accuracy directly. The higher the point accuracy is, the better the detail is.

3. Size adaptability

If the scanned object is larger than 4 m, the cumulative alignment error may be larger, which may require a global photogrammetry system; the precision requirement is higher for objects within 0.3 m.

4. Environment adaptability

Is the scanning process taking place outdoors or indoors? Whether there is direct sunlight? Is it possible to control the airflow at the work site (The airflow is likely to float the leaves)?

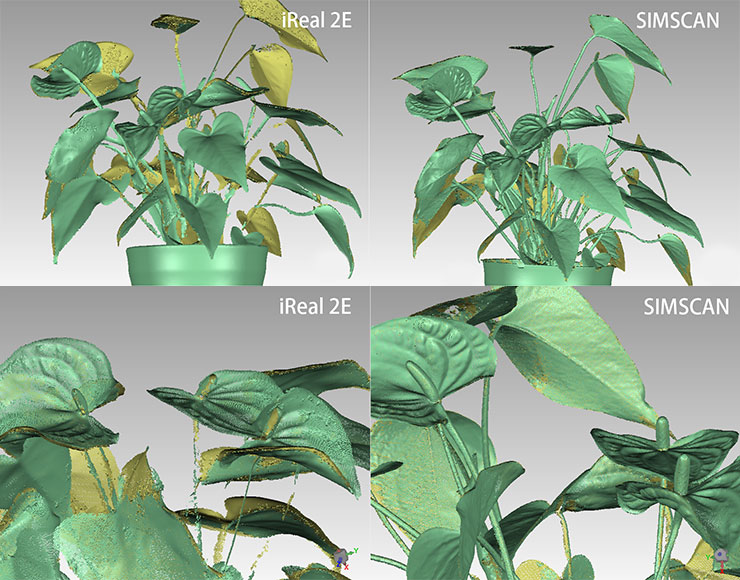

Comparison between iReal 2E and SIMSCAN in plant scanning

Test 1

In the video below, our application engineerers conducted a plant scanning test to compare the data capturing abilities of iReal 2E and SIMSCAN.

Test 2

To obtain more rigorous data, our application engineerer did another test the other day to better compare the two 3D scanners.

3D scanning the plant with iReal 2E 3D scanner:

3D scanning the plant with SIMSCAN 3D laser scanner:

Scanning result

After the scanning, we compared the two sets of data. And we have drawn a conclusion that BOTH can 3D scan without sticking markers on plants. iReal 2E performs feature alignment based on the geometric features of the plant and features constructed by itself, so it can 3D scan without markers; and SIMSCAN can do marker alignment based on the marker points on the auxiliary frame, and it can also scan without markers on plants.

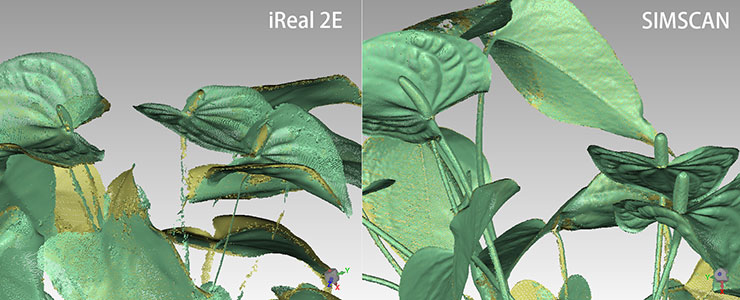

As for the data analysis, we will study the data from the perspective of data integrity.

As the photos show, for slender stems, SIMSCAN can scan more completely, and the obtained plant surface features are richer.

The leaves and stems can be scanned more completely by SIMSCAN, and the surface features obtained are richer.

Reasons for the result

1. The camera distance of SIMSCAN scanner is smaller: the distance between the two cameras of SIMSCAN is relatively small (only 130 mm), so the common view field of the two cameras will be more during the scanning process, and the less the camera is blocked, the more complete the data will be scanned;

2. SIMSCAN has a single-line laser scanning function: SIMSCAN has a stronger scanning ability for the deep holes and dead corners: After testing, the hole depth ratio of SIMSCAN is about 1:2.1, and the hole depth ratio of iReal 2E is about 1:1.2;

3. The point accuracy of SIMSCAN is higher: SIMSCAN has a maximum accuracy of 0.02mm, which is much higher than iReal point accuracy (maximum accuracy of 0.1mm). Therefore, for thin and small features, the points at these positions can be accurately calculated, and the final result of SIMSCAN is more complete;

4. The number of scanning angles of SIMSCAN is larger: as long as the markers are fully stuck, the scanning angle can be more, and the data obtained by scanning will be more complete; for iReal 2E, the scanned object needs to have enough geometric features to make sure the scanning result is good, so the number of scanning angle is limited, and the integrity of the data will naturally be low.

3D scanner model selection suggestion

If you don’t have enough budget, you can consider buying iReal 2E first, and then upgrade to the laser 3D scanner later; If you have sufficient budget, you can buy a laser 3D scanner, and then you can obtain 3D models of plants with higher data integrity, and conduct more comprehensive data analysis.

Related Articles

View Our Product